FLEXIBLE RUBBER EXPENSION JOINTS

Definition & Applications

A rubber expansion joint is an arch-type flexible non-metallic connector fabricated from natural or synthetic rubber and fabrics, usually with metal reinforcements, to isolate vibration and noise and provide stress relief in piping systems caused by thermal changes, mechanical vibration and other system movements. Generally, it shall be designed & fabricated in accordance with ASTM F1123 and “Technical Handbook on Rubber Expansion Joints and Flexible Pipe Connectors”, or in accordance with special customer requirements. Besides, the Chinese standard HG/T 2289 Flexible Rubber Joints sometimes may apply.

Rubber expansion joints provide flexibility and concurrent

movements, isolation of vibration and noise, resistance to corrosion, abrasion

and erosion in various piping systems. They are widely used in process piping

systems, urban heating & air conditioning systems, water supply systems,

sewage treatment, food industry, ship building industry, power generation, as

well as pharmaceutical industry.

Construction Features

The 3-dimensional model of a spool arch type rubber expansion

joint. The sectional view of the inner tube, carcass and cover.

Miscellaneous design patterns of rubber expansion joints are available: (1) Integral Rubber Flanges – The end connection flanges of the joint are integrally formed as a part of the elastomeric bellows. It is also called “spool arch type rubber expansion joint”. (2) Floating Metallic Flanges – The metal flanges shall have a groove to accept the molded bead in the body at each end of the expansion joint bellows. (3) Spherical Type – Long radius arch, either single sphere or twin sphere, to provide better movement capability and strength. (4) Control Units – Tie rods or control rods are provided to minimize possible damage to the expansion joint caused by excessive motion of the piping system. (5) Custom Designs – rectangular flange connection, threaded union connection, tapered reducer type, no-arch U type, hinged type, gimbal type, sleeve type, PTFE lined type.

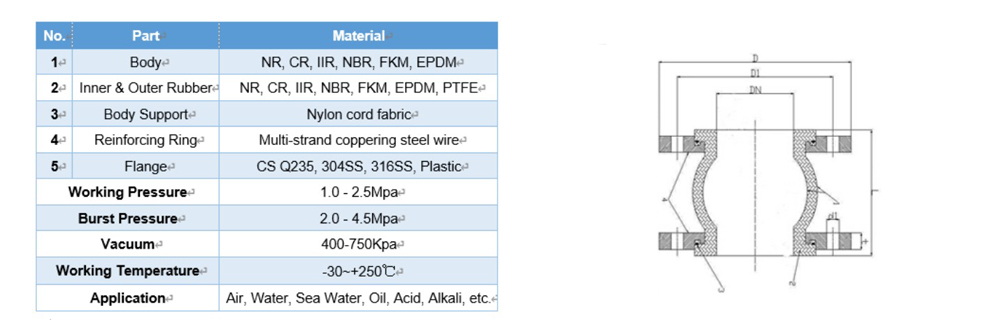

Diagrammatic Drawing & Technical Parameter

DN

Length

Axial Displacement mm

Horizontal

Displacement

mm

Angular

Deflection

(a1+a2)°

mm

inch

mm

Extension

Compression

32

1.25

95

6

9

9

15

40

1.5

95

6

10

9

15

50

2

105

7

10

10

15

65

2.5

115

7

13

11

15

80

3

135

8

15

12

15

100

4

150

10

19

13

15

125

5

165

12

19

13

15

150

6

180

12

20

14

15

200

8

210

16

25

22

15

250

10

230

16

25

22

15

300

12

245

16

25

22

15

350

14

255

16

25

22

15

400

16

255

16

25

22

15

450

18

255

16

25

22

15

500

20

255

16

25

22

15

600

24

260

16

25

22

15

700

28

260

16

25

22

15

800

32

260

16

25

22

15

900

36

260

16

25

22

15

1000

40

260

18

26

24

15

1200

48

260

18

26

24

15

1400

56

350

20

28

26

15

1600

64

350

25

35

30

10

Working Principle

Production Process

BETTER Drilling Fluid Solution Limited

BETTER Drilling Fluid Solution Limited