DOUBLE ACTING PNEUMATIC ACTUATOR AT SERIES

BETTER butterfly valve are combined with AT series double acting pneumatic actuator, which is produced with the latest technology at home and abroad.

Feature

Preloaded coating springs are made from high quality material for resistance to corrosion and longer service life, which can be demounted safely and conveniently to satisfy different requirements of torque by changing numbers of springs.

ISO5211 is suitable for butterfly valve

DIN3337 and NAMUR for pneumatic accessories

Twin rack positions are made from die-casting aluminum rated with hard anodized or made from cast steel with galvanization, symmetric mounting position, long cycle life and fast operation, reversing rotation by simply inverting the pistons

It is has a number of springs inside and will auto return once air is interrupted and it could keep the valve and project safe.

Specification

Air supply pressure: 2.5 to 8 bar

Output torque: 14 to 1170 Nm

Lifespan: 1 million times

Angle of rotation: 90 degrees +/- 4

Shell material: Aluminum alloy steel extruded

Connections: NAMUR, ISO5211, DIN3337

Color: Gray, Black, Blue, Red, Orange

Standard: CE and ISO

Application: filtered, dry compressed air, no-corrosive medium

Ambient temperature: Normal Temperature: -20ºC(-4°F) ~ 80ºC (+176°F); High Temperature: -15ºC(+5°F) ~ 150ºC (+302°F); Low Temperature: -40ºC(-104°F) ~ 80ºC (+176°F)

Lubrication: No lubrication needs for standard type under normal operation condition, but special lubricants should be used under low or high temperature operation conditions.

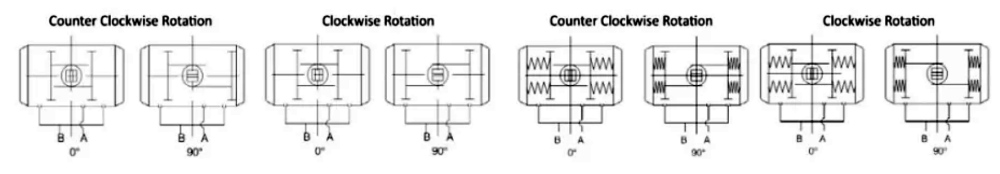

Working Principle

Double acting and spring return

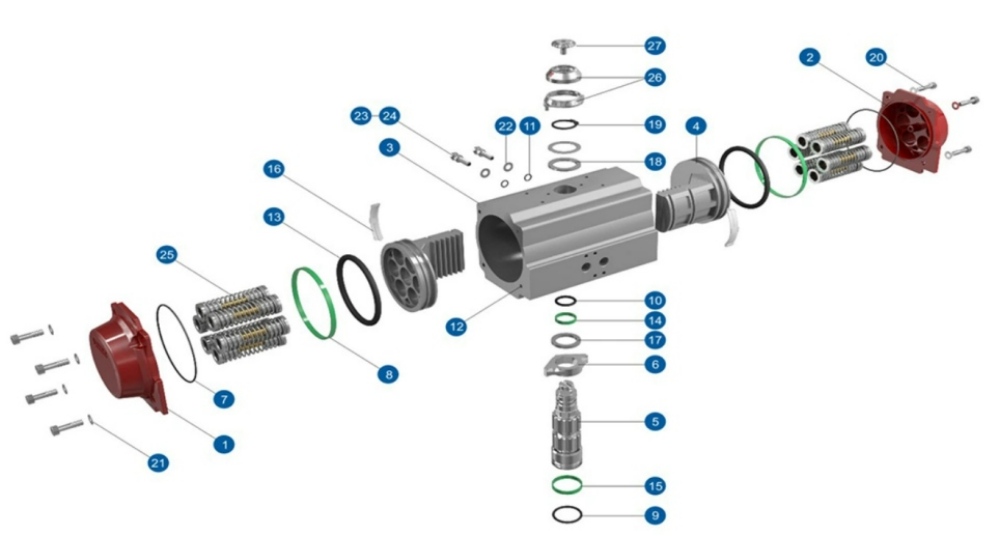

Material List

|

Item |

Qty. of each |

Part Name |

Standard Material |

|

1 |

1 |

Left Cover |

Alumium Die Casting |

|

2 |

1 |

Right Cover |

Alumium Die Casting |

|

3 |

1 |

Cylinder |

Alumium alloy extruded |

|

4 |

2 |

Piston |

Alumium Die Casting |

|

5 |

1 |

Output Shaft |

Carbon steel |

|

6 |

1 |

Cam adjustment |

Stainless Steel |

|

7 |

2 |

O-ring F/Cover |

NBR |

|

8 |

2 |

O-ring F/Piston |

NBR |

|

9 |

1 |

O-ring (output shaft bottom) |

NBR |

|

10 |

1 |

O-ring (output shaft top) |

NBR |

|

11 |

2 |

O-ring(Adjusting screw) |

NBR |

|

12 |

2 |

Plug (Cylinder) |

NBR |

|

13 |

2 |

Bearing (Piston) |

|

|

14 |

1 |

Bearing( Output shaft at the top) |

Nylon46 |

|

15 |

1 |

Bearing( Output shaft bottom) |

Nylon46 |

|

16 |

1 |

Guide with bearing(Piston Back) |

Nylon46 |

|

17 |

2 |

Thrust bearing(output shaft) |

Nylon46 |

|

18 |

2 |

Gasket(output shaft_ |

NBR |

|

19 |

1 |

Flexible file ring |

NBR |

|

20 |

8 |

Cober Bolt |

Stainless steel |

|

21 |

8 |

Cover gasket |

NBR |

|

22 |

2 |

Gasket |

NBR |

|

23 |

2 |

Nut |

NBR |

|

24 |

2 |

Adjustment bolt |

|

|

25 |

5-16 |

Spring components |

Stainless steel |

|

26 |

1 |

Position indicator |

PPPP+30%GF |

|

27 |

1 |

Screw if indicator |

PPPP+30%GF |

Model\Air Pressure

Air Supply Pressure

(Unit: Bar)

2.5

3

3.5

4

4.5

5

5.5

6

7

8

AT-32D

3.8

4.5

5.3

6.0

6.8

7.5

8.3

9.0

10.5

12.0

AT-50D

8.3

10.0

11.6

13.3

15.0

16.6

18.3

20.0

23.3

26.6

AT-63D

14.6

17.6

20.5

23.4

26.4

29.3

32.2

35.2

41.0

47.0

AT-75D

29.0

35.0

40.7

46.5

52.3

58.1

64.0

69.7

81.4

93.0

AT-88D

45.7

55.0

64.0

73.2

82.3

91.4

101

110

128

146

AT-100D

66.4

79.7

93.0

106

120

133

146

159

186

213

AT-115D

107

129

150

172

193

215

236

258

301

344

AT-125D

138

166

194

221

249

277

304

332

387

443

AT-145D

217

261

304

348

391

434

478

521

608

695

AT-160D

283

340

397

453

510

577

623

680

793

907

AT-190D

533

640

746

853

959

1066

1173

1279

1492

1706

AT-210D

651

781

911

1042

1172

1302

1432

1562

1823

2083

AT-240D

957

1148

1339

1530

1722

1913

2104

2296

2678

3061

AT-270D

1452

1743

2033

2324

2614

2905

3195

3486

4067

4648

AT-300D

1993

2391

2790

3188

3587

3985

4384

4782

5579

6376

BETTER Drilling Fluid Solution Limited

BETTER Drilling Fluid Solution Limited